Etiquetado: 95 caballos de eléctrico, arrestado en Alabama, Daimerl, Daimler, Daimler cerrará Maybach en 2013, Ejecutivo alemán de Mercedes-Benz, El lanzamiento mundial del Mercedes SLK será en Tenerife, Finaliza la producción de la primera generación del CLS, Futuro incierto para la marca Maybach, Lexus, Maybach, mercedes bez, Mercedes Clase A E-Cell, mercedes group noticias, mercedes grupo noticias, Mercedes prepara la resurrección de Maybach, Mercedes se queja de la gasolina vendida en EEUU, Mercedes trabaja en una caja de cambios de nueve marchas, Mercedes-Benz, Mercedes-Benz adelanta a Lexus en EEUU, Noticias Daimler, Noticias grupo mercedes, Noticias MERCEDES BENZ-Smart, NOTICIAS Mercedes-Benz, Noticias Mercedes-Benz Group, Nueva gama mecánica de Mercedes-Benz, Nuevos 4.6 V8 y 3.5 V6 de Mercedes, Resurreccion, Smart, Smart tendrá un cinco puertas para EEUU con base Micra

- Este debate tiene 335 respuestas, 52 mensajes y ha sido actualizado por última vez el hace 12 horas, 14 minutos por

A.P.M..

A.P.M..

-

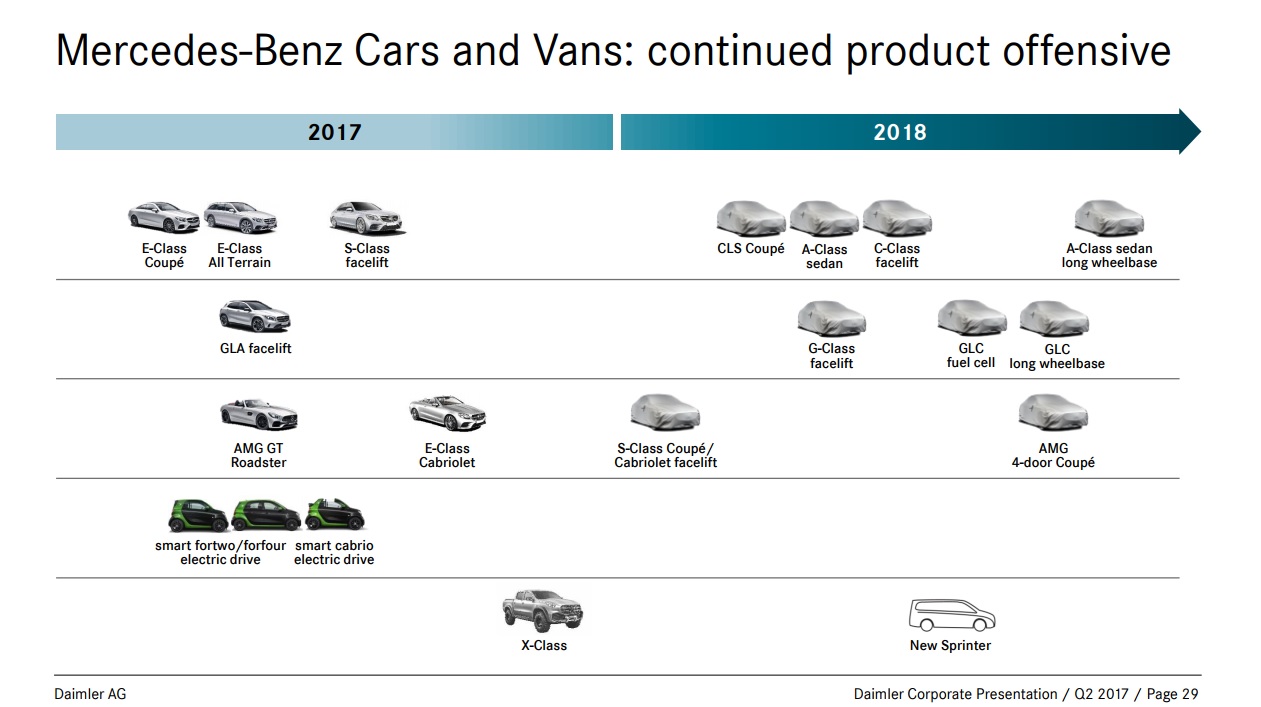

Mercedes dice que cometió un error, y donde ponia GLA coupe queria decir facelift 😀

https://3.bp.blogspot.com/-94kbhpPtdG0/V5XRaTLRL_I/AAAAAAAAhPQ/MD0glahZh8wgVrSxfmPcxQB4Ri4kHcZJACLcB/s1600/2017-daimler-road-map.jpg http://www.carscoops.com/2016/07/merc-gla-coupe-replaced-by-gla-fl-in.html Ahora encaja mejor la cosa

Esta es la hoja de ruta de la familia A de Mercedes, según Autobild

• Clase A de cinco puertas: abril2018

• Clase A Sedán: Octubre 2018

• Clase B: Febrero 2019

• CLA: Abril 2019

• CLA Shooting Brake : Julio 2019

• GLB (Crossover): septiembre 2019

• GLA: Abril 2020http://www.autobild.de/artikel/mercedes-a-klasse-w177-2018-vorschau-5253647.html Por lo que se ve, volvemos a no tener el 3p, algo logico si el resto de compactos lo va perdiendo (aunque el concept de la generación anterior anda que no molaba), pero aparece un sedan aparte del CLA, asi que supongo que será el sedan normal y el sedan deportivo, como pasa con el E y el CLS

Mercedes presenta sus nuevos motores

Es una nueva familiar de motores con 500cc por cilindro:

– Los 3.0 pasan a ser en L

– Se añade el filtro de particulas

– Sistema electrico de 48vNuevas mecanicas:

– M 264: 2.0 4L turbo: 134cv por litro

– M 256: 3.0 6L turbo: 408 hp y mas de 500 Nm. Lleva compresor electrico

– M 176: 4.0 V8 biturbo: 476 hpy alrededor de 700 Nm. Lleva sistema de desconexión de cilindros

– OM 656: 3.0 6L d biturbo: 313hpNota de prensa, en inglés

Extensive strategic engine initiative from Mercedes-Benz: More powerful, more economical and cleanerStuttgart/Sindelfingen. The biggest strategic engine initiative in the history of Mercedes-Benz will enter its decisive phase in 2017. Following the launch of the new four-cylinder diesel engine in spring 2016, next year will see the addition of no fewer than four more members to the all-new family of engines: six-cylinder in-line engines in both diesel and petrol versions, a new four-cylinder petrol engine and a new biturbo V8. At the same time, there will be world premieres for ground-breaking technologies, such as the Integrated Starter-Alternator (ISG), the 48 V electrical system and the electric auxiliary compressor (eZV). These new technologies are tuned to the vehicles on state-of-the-art test rigs at the equally new Powertrain Integration Centre (AIZ) in Sindelfingen.

«More powerful, more economical and cleaner – the new modular family of engines from Mercedes-Benz offers the right powertrain for every vehicle,» says Prof. Dr Thomas Weber, 62, Member of the Daimler Board of Management with responsibility for Group Research at Daimler AG and Mercedes-Benz Cars Development. «The systematic optimisation of our high-tech engines plays a crucial role in the road map towards sustainable mobility. They also need to be designed with a view to all current and future requirements. A key success factor in this regard is the extensive electrification of the powertrain.»

Systematic electrification: new six-cylinder in-line petrol engine M 256The new six-cylinder in-line petrol engine M 256 represents an outstanding example of electrification, including a 48 V electrical system. New, intelligent turbocharging, e.g. with an electric auxiliary compressor (eZV), as well as an Integrated Starter-Alternator (ISG) provide the guarantee of excellent drivability with no turbo lag. The ISG is responsible for hybrid functions, such as boost or energy recovery, while allowing fuel savings that were previously reserved for high-voltage hybrid technology. The bottom line is that the new six-cylinder in-line engine offers the same performance as an eight-cylinder machine while being much more fuel-efficient. The new petrol engine (internal code: M 256) launches next year in the new S-Class.

Systematic electrification dispenses with the need for a belt drive for ancillary components at the front of the engine, which reduces its overall length. The narrow construction, together with the physical separation of intake/exhaust, creates space for near-engine exhaust aftertreatment. The 48 V electrical system serves not only high power consumers, such as the water pump and air-conditioning compressor, but also the Integrated Starter-Alternator (ISG), which also supplies energy to the battery by means of highly efficient energy recovery.

An additional bonus is the unsurpassed refinement of the six-cylinder in-line engine. Output and torque are similar to the current eight-cylinder engine, i.e. over 300 kW (408 hp) and more than 500 Nm. In comparison with the previous V6, the CO2 emissions from the engine have been reduced by around 15 percent.

At 500 cc, the new machine has the same displacement per cylinder as the premium diesel engine family unveiled last year as well as the family of four-cylinder petrol engines.

Most powerful passenger-car diesel engine in the history of Mercedes-Benz: six-cylinder OM 656The new top-of-the-line engine in the premium diesel family is likewise a six-cylinder in-line machine. The characteristics of the OM 656 include the stepped-bowl combustion process, two-stage exhaust turbocharging and, for the first time, the use of CAMTRONIC variable valve timing. Its design features a combination of aluminium engine block and steel pistons as well as further-improved NANOSLIDE® coating of the cylinder walls. Although there is a significant increase in output compared with the previous OM 642 (over 230 kW/313 hp instead of 190 kW/258 hp), the new engine consumes more than seven percent less fuel.

Like the already unveiled four-cylinder OM654, the new six-cylinder diesel engine OM 656 is likewise designed to comply with future emissions legislation (RDE – Real Driving Emissions). All the components of relevance for efficient emissions reduction are installed directly on the engine. The integrated technology approach of new stepped-bowl combustion process, dynamic multi-way exhaust gas recirculation and near-engine exhaust aftertreatment, combined for the first time with variable valve timing, opens the way for further reductions in consumption together with extremely low emissions. Thanks to the near-engine insulated configuration, exhaust aftertreatment has a low heat loss and extremely favourable operating conditions. This is reinforced by the CAMTRONIC switchable exhaust camshaft, which supports the consumption-neutral heating of the exhaust system.

Number of cylinders to suit the requirements: new V8 biturbo petrol engine M 176Dynamic power delivery combined with high efficiency: the new biturbo (internal code: M 176) is one of the most economical V8 petrol engines in the world. Its special features include cylinder shutoff at part load as well as the positioning of the turbochargers in the V between the cylinder banks. From its 3982 cc displacement, the new V8 biturbo produces over 350 kW (476 hp) with a maximum torque of around 700 Nm from 2000 rpm. The new engine will consume over 10 percent less fuel than its predecessor, which is rated at 335 kW (455 hp). The new V8 will launch with this technology next year in the new S-Class.

For lower fuel consumption, when operated at part load the new M 176 shuts off four cylinders simultaneously by means of CAMTRONIC valve timing. This reduces the pumping losses while improving the overall efficiency of the remaining four cylinders by shifting the operating point towards higher loads.

Sporty specific output: new four-cylinder petrol engine M 264A two-litre four-cylinder engine with a specific output of around 100 kW: the new Toptype petrol engine from Mercedes-Benz (internal code: M 264) advances into output regions previously reserved for high-displacement six-cylinder machines. At the same time, it consumes significantly less fuel than a comparable six-cylinder engine. The engine’s special features include twin-scroll turbochargers, belt-driven 48 V starter-alternator (BSA) and electric 48 V water pump.

The BSA is also responsible for fuel-saving hybrid functions:

– Easy start: virtually imperceptible starting and acceleration of the engine

– Boost in the engine-speed range up to 2500 rpm

– Energy recovery up to 12.5 kW

– Shifting of the load point: allows operation in a more favourable area of the engine map

– Coasting with engine off.In the interests of high power output and a spontaneous engine response, Mercedes-Benz has opted for twin-scroll turbocharging. Unlike conventional systems, a twin-scroll turbocharger merges the exhaust gas ducts of cylinder pairs in the flow-optimised manifold. This turbocharging concept with systematic cylinder flow separation produces high torque in the low-rpm range together with high specific output. Further efficiency measures include intake CAMTRONIC and a friction loss reduction package.

Even cleaner: particulate filter for petrol engines as standardMercedes-Benz is the first manufacturer to opt for the large-scale use of particulate filters for petrol engines to further improve their environmental compatibility. After more than two years of positive experience in the field with the S 500, in 2017 further S-Class variants will be equipped with the new M 256 and M 176 petrol engines with this technology. The filter will then be gradually introduced in other new vehicle models, facelifted models and new engine generations, such as the M 264.

The particulate filter for petrol engines reduces the emissions of fine soot particles. How it works: the exhaust-gas stream is supplied to a particulate filter system. The filter has a honeycomb structure with alternately sealed inlet and outlet channels. This forces the exhaust gas to flow through a porous filter wall, which traps the soot. The filter can be continuously regenerated under corresponding driving conditions.

New Powertrain Integration Centre (AIZ): state-of-the-art test rigsWith its new Powertrain Integration Centre (AIZ), in summer 2016 Mercedes-Benz took into service one of the automotive industry’s most advanced test facilities. A total of ten vehicle test rigs inside the all-new state-of-the-art building in Sindelfingen are used for such purposes as the fine tuning of engine and transmission – comfort, dynamics and agility are matched to each other. The highlights include test rigs with high-precision torque measurement directly at the wheels of the vehicle as well as a test rig with a climatic altitude chamber, which uses partial vacuum to simulate an altitude of up to 5000 metres at temperatures of down to -30°C, while the vehicle operates fully automatically on a chassis dynamometer.

The new building at the Sindelfingen Mercedes-Benz Technology Centre (MTC) houses ten vehicle test rigs for tuning vehicles and their powertrains. The new building used 16,800 m3 of concrete, equivalent to the capacity of five Olympic swimming pools. There were also 2500 tonnes of reinforcing steel. The designers of the AIZ attached great importance to energy recovery, with 98 percent of the electric braking energy produced on the test rigs being fed back into the power network. Also, the air conditioning of the test rigs is energy-neutral for two-thirds of the year, which means that no power is consumed from the joint network. With all ten test rigs in continuous operation, this would be the same as supplying around 7500 households with electricity.

La plataforma MFA2 dispondrá de más modelos, 8Lo acaba de confirmar Britta Seeger en el salón estadounidense

Asi que así podria quedar la gama:

– A

– A sedan

– B

– CLA

– CLA Shooting brake

– GLA

– GLBMe quedaria uno ¿B 7 plazas? ¿SLA?

http://www.carscoops.com/2017/01/mercedes-to-add-four-door-sedan-and-suv.html La plataforma MFA2 dispondrá de más modelos, 8Lo acaba de confirmar Britta Seeger en el salón estadounidense

Asi que así podria quedar la gama:

– A

– A sedan

– B

– CLA

– CLA Shooting brake

– GLA

– GLBMe quedaria uno ¿B 7 plazas? ¿SLA?

http://www.carscoops.com/2017/01/mercedes-to-add-four-door-sedan-and-suv.html Según Autopista el GLB es 7 plazas.

La plataforma MFA2 dispondrá de más modelos, 8Lo acaba de confirmar Britta Seeger en el salón estadounidense

Asi que así podria quedar la gama:

– A

– A sedan

– B

– CLA

– CLA Shooting brake

– GLA

– GLBMe quedaria uno ¿B 7 plazas? ¿SLA?

http://www.carscoops.com/2017/01/mercedes-to-add-four-door-sedan-and-suv.html Según Autopista el GLB es 7 plazas.

Al parecer, proponian 2 versiones, una de 5 y otra larga de 7 plazas

Pero claro, solo Mercedes sabe lo que hay preparado. Bueno, y Autobild algo sabrá tambien😀 Osea que se llamara cls como hasta ahora y no cle como se especulaba, y que es lo de long wheel base?, modelos para china supongo… A mi lo que me llama mucho la atención es lo que acompaña al G-Class, Facelift. Estaba seguro que sería un modelo nuevo, aunque muy similar… A mí también me llama la atención lo de G facelift. Y también no leer nada de un nuevo CLA… ¿será que el A sedán ocupará ese hueco?

Y el Clase A 5 puertas? No saldrá hasta 2019? Es todo muy raro. Rumorlogia: parece que Mercedes seguiria pensando en un utilitario

Para ello, podria acortar la plataforma modular del A. Dice que deberia estar sobre los 20.000€. PEro tambien dice que puede ser algo dificil porque es una base cara, y que podria ahí intervenir las sinergias con otros grupos. Y entraria Renault-Nissan a escena.

Dicen que podria ser un utlitario de 3 puertasnoticia en alemán

http://www.autobild.de/artikel/mercedes-kleinwagen-a-city-2022-vorschau-13730461.html Creo que llevan años habandose de esta posibilidad, pero creo recordar que Mercedes dijo que no entraria en ese estrato. Pero siguen los rumores…

Genial, un Clio con la estrella y 5000 euros más caro. ¡Todo ventajas! Con motivo del 35º encuentro anual de tecnologia, Mercedes ha dado un paso al frente en lo que se refiere a la gama mecanica venidera, hasta que solo existan mecanicas electrificadas Dieter ha comentado que habrá una simplificación masiva en la gama, pues la hibridación tomará mucho protagonismo

No se ha cortado a la hora de explicar en que consistirá. La asociación con Renault y Nissan le están trayendo solo cosas positivas, asi que tambien habrá una parte en esta nueva gama mecanicaEl primer motor que habrá, será el 1.3 turbo (aunque lo denominan 1.4). Tendrá varias versiones, con solo sistema de 48v y varias con motor electrico acoplado. El siguiente escalón mecanico será el 2.0 turbo de la casa, ya con uno o varios motores electricos acoplados. El ultimo motor de la gama normal (AMG es aparte) seria el 3.0 6L biturbo con 2 motores electricos. Todos irian con el sistema de 48v logicamente, y salvo los basicos, los demás serán plug-in

Ha especificado un poco, detallando que el 1.3 turbo llegará hasta los 225cv en la versión mas alta de los hibridos (163cv + electrico), mientras que el base será el 136cv con sistema de 48v. Uno de los hibridos lo conoceremos en 2019

En cuanto al 2.0 turbo, no habrá un base con solo 48v, sino que habrá una versión con un motor electrico y otro con 2. Las potencias estarán entre los 280cv y los 400cv

En el caso del 3.0, la actual versión de 48v se hibridará de mayor manera, pues dispondrá de 2 motores electricos. Segun indica, ofreceria casi 500cvSegun Dieter, la nueva gama mecanica está destinada a ofrecer unas prestaciones acordes a lo que se espera en un Mercedes, y unos consumos que puedan permitir pasar las diferentes homologaciones en años venideras. Además, forma parte del proceso de evolucion en la electrificación, pues aunque esté desarrollandose la gama EQ, al final todo modelo será electrico. Segun sus palabras, la gente todavia no está capacitada para ver un clase S con una autonomia de 450km y un tiempo de recarga de 4-5h, sin embargo, en unos 10 años, puede que la autonomia haya se duplicado , y el tiempo de recarga disminuido enormemente, asi que ya seria bien visto.

Un clase S de nueva generación, con el 2.0T hibrido base es de esperar que ofrezca una autonomia electrica ya de 150km¿Y el diesel? Dice que seguirán desarrollandolo, siguen teniendo planes de mejora para él, como la hibridación al estilo de la gama de gasolina. De hecho, ya hay en la actualidad una versión a la venta

Noticia:

[url url=https://zaragozabuenasnoticias.com/2015/12/28/inocente-inocente/]35º Simposium electrodigital de Burn[/url] Lo de los híbridos de 48v es algo que vamos a ver en muchas marcas, y que sigan desarrollando el diésel me parece curioso, pero lo veo bien. Sacar casi 500Cv de un 6 en linea hibridado está bien, pero donde quedan los V8??? La verdad es que es muy interesante desde luego, el enlace aclara todas las dudas sobre el futuro de estas mecánicas. BMW i2 y Mercedes EQA, los dos primeros eléctricos de la alianza llegarán en 2024.

La nueva alianza firmada entre Daimler y BMW para la producción de vehículos eléctricos y profundizar en la tecnología de conducción autónoma ya da sus los primeros frutos con los futuros BMW i2 y Mercedes EQA, dos utilitarios Premium completamente eléctricos con un precio inferior a 30.000 euros.

https://www.motor.es/noticias/bmw-i2-mercedes-eqa-2024-adelanto-201956069.html

Smart dice adiós a los Estados Unidos y Canadá.

La nueva hoja de ruta establecida por Daimler y Geely para Smart pasa por finalizar las operaciones de la marca en dos países clave del continente americano. Smart dirá adiós a los Estados Unidos y Canadá. La conversión en una marca 100% eléctrica no ha funcionado en el mercado norteamericano.

Noticia completa: https://www.motor.es/noticias/smart-estados-unidos-canada-201956958.html

Dicen que hay rumores de que la alianza con Renault podría estar en juego tras la jubilación del presi de Mercedes y con Gosh en la carcel que ambos fueron los que la crearon.

AMG tendrá versiones electricas

Según comentó Ola Källenius a Autocar, los modelos AMG tendrán algo más que hibridación, habrán versiones electricas

“We have to get to the point where the means of propulsion is not considered important, because AMG is all about the experience of customers. That is why we are starting to work not just on electrified AMGs but also our first fully electric AMGs.”

Yo también sé decir que lo van a dejar de hacer sin dar una fecha?

- Regístrate para participar en el debate, puedes iniciar sesión desde el menú superior derecho o registrándote desde el botón "Regístrate" en el final de la página.